Recognizing when to replace your current automation machinery is crucial for maintaining productivity in manufacturing operations. One clear sign of problems is an increase in downtime due to frequent breakdowns or the need for repairs. When machinery starts requiring constant repairs, not only does it limit production, but it also increases maintenance costs.

Old Technology Issues

A factor that is often overlooked is the problem that occurs when machinery technology becomes obsolete. As technological advancements continue to evolve, older machinery in Cleveland, OH, businesses may not be compatible with new software or processes, limiting your operation’s potential for growth and efficiency. This can also lead to difficulty finding replacement parts or technical support for outdated equipment.

Drop in Quality

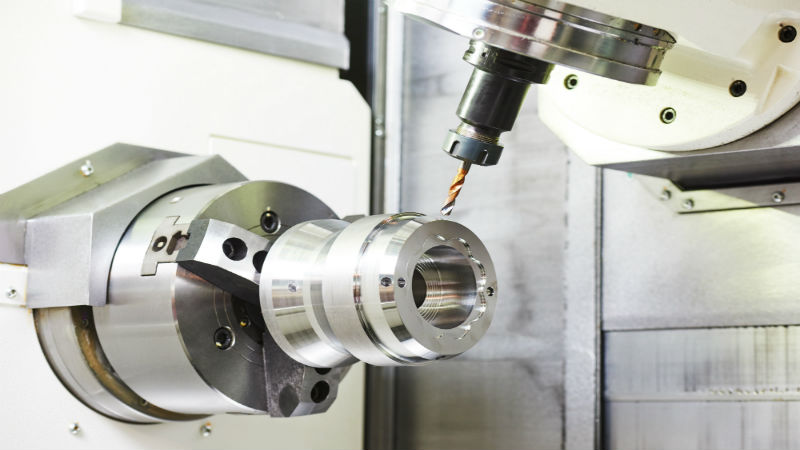

Product quality or consistency decline is often related to outdated automation machinery in Cleveland, OH. Automated machinery and processes that can no longer meet the required production standards can affect your business’s production and ability to stay on schedule.

A decrease in efficiency or an increase in energy consumption can also signal that machinery is nearing the end of its useful life. Newer models or automation machinery in Cleveland, OH are designed to be more energy-efficient, providing the same or better performance while reducing operational costs.

Avoiding problems with older machinery and processes is the best way to prepare your Cleveland, OH, business for the future. It is also critical when your business is growing or expanding production. It effectively allows you to stay ahead of product demand and take advantage of market opportunities.

If you need more information on how new options in automation machinery can enhance your business, talk to the experts at Big Sky Engineering. Additional details on our services can be found at bigskyeng.com.

Connect with Big Sky Engineering, Inc. on Facebook for more information.